What is Grade A Tile? What about Grade B Tile?

First and foremost, no single factory will intentionally produce tiles in Grade B (2nd Grade Tile). Factory’s main aim is to manufacture Grade A (1st Grade) tiles, or in other words, to achieve 100% of that in their production yield. However, this is not possible in reality. Imperfection can happen in production, and the Grade A tiles yield may fluctuate between 94% to 97%, which is considered a remarkable production output. The remaining 3% to 6% output is either downgraded to be sold as Grade B tiles or rid of as rejected tiles.

Grade A tile fetches a much higher premium than Grade B tile in the market. As in all fired products, tiles are bound to have tolerances due to shrinkages amid production and can be classified to its grading accordingly in adherence to a set of international standards, namely Malaysian Standard MS ISO 13006, in this case here. Now, allow us to dwell deeper into the topics or criteria that set Grade A away from Grade B tiles that we can observe through their physical appearances.

Let us concentrate on the generic product of tiles here for analysis and comparison purposes. For tiles technical specifications details, one can refer to the link in our Leo Ceramiko’s website here.

1. TOPIC: DIMENSION

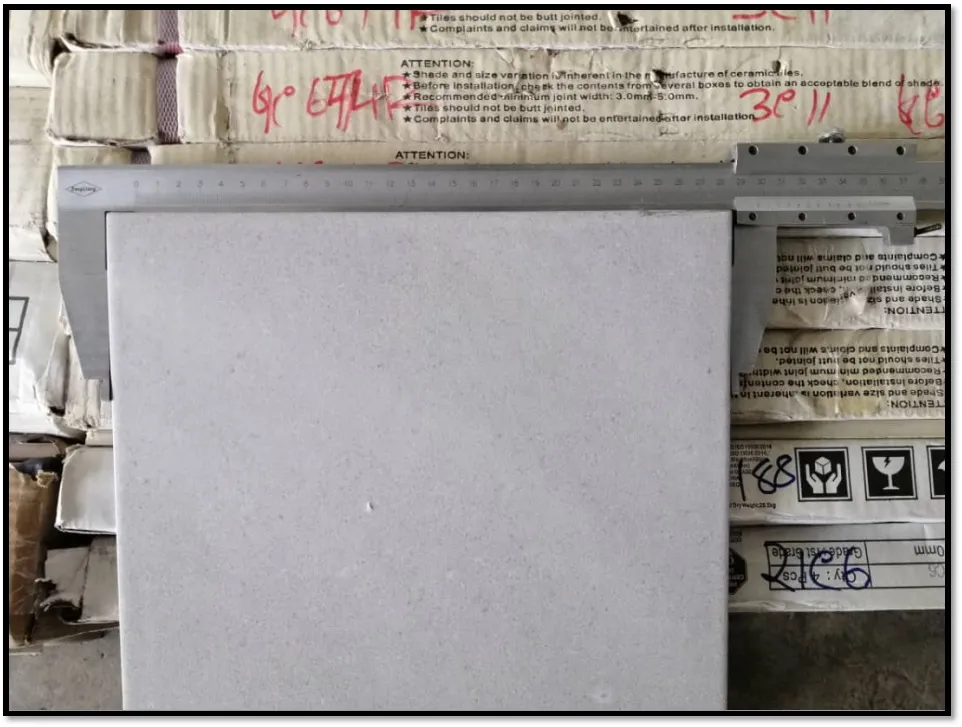

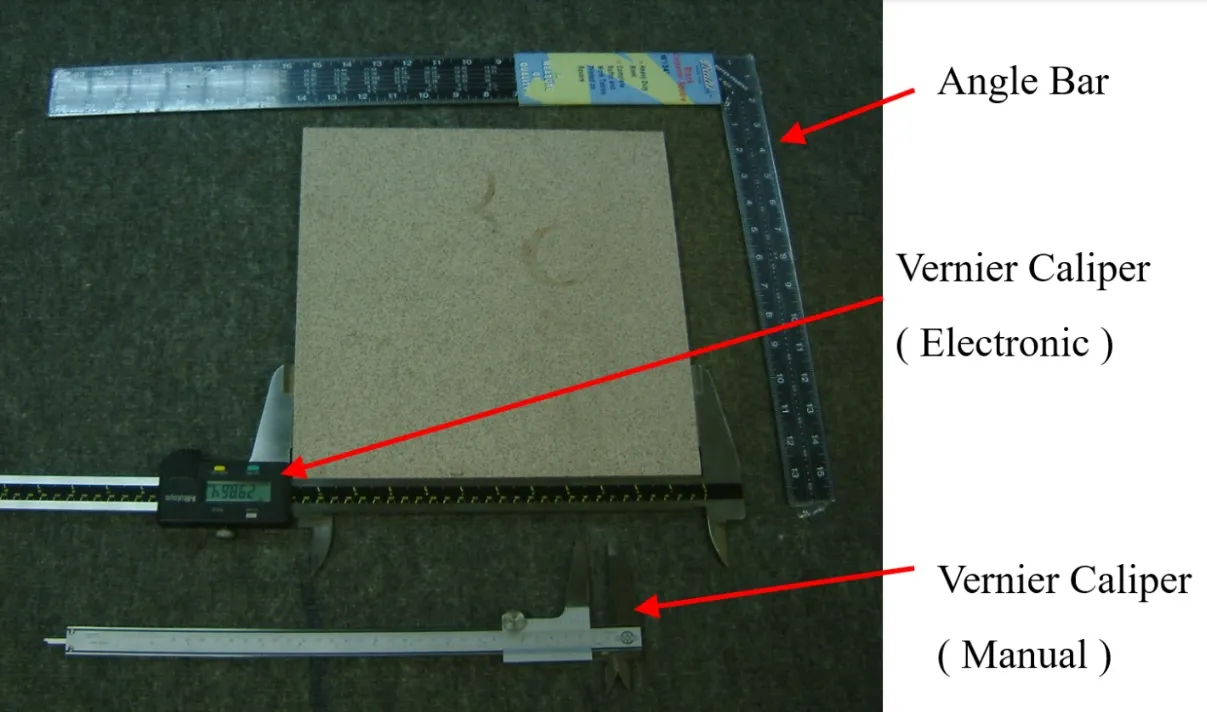

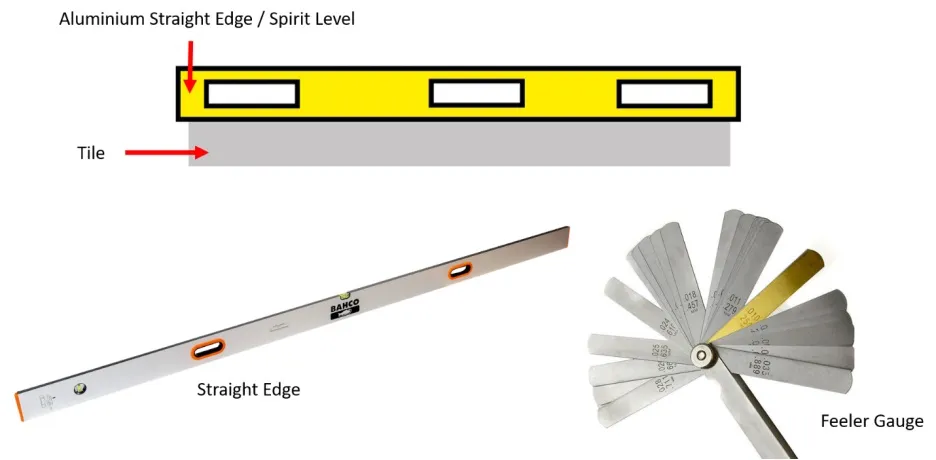

Picture 1: Equipment used in determining dimension

- We measure the dimension of tiles using the above equipment to determine 3 criteria which are:a) Length and Widthb) Straightness of Sidesc) Rectangularity

a) In length and width, tiles with a nominal size of 600x600mm will allow a tolerance of ± 0.5% in Malaysian Standard; MS ISO 13006. In other words, it provides for ± 3mm in absolute terms based on the mentioned tile size. If we zoom in to our LEO Ceramiko’s specs of ± 0.25%, we will only allow ± 1.5mm tolerances in Grade A tiles and anything that surpasses it will downgrade as Grade B tiles. Our tile products are capped at ± 1mm to ensure an extremely high-quality standard.

-

Picture 2: Manual Caliper used in measuring Length and Width

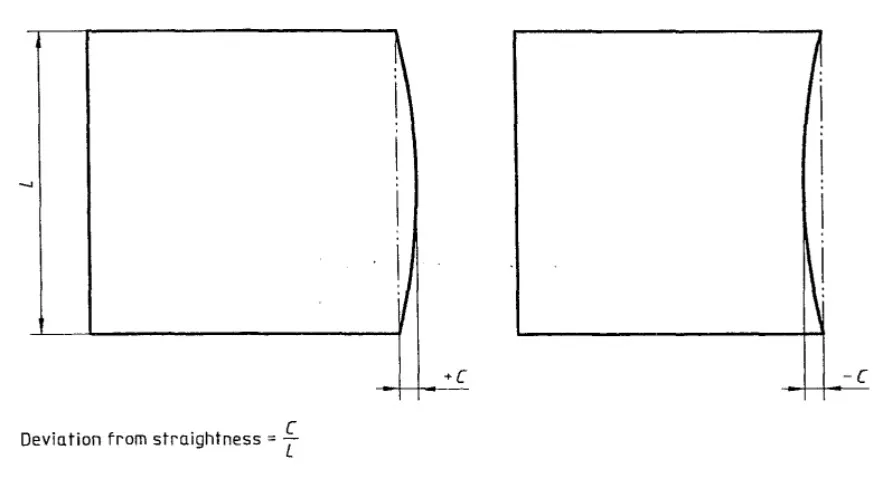

b) In length and width, tiles with a nominal size of 600x600mm will allow a tolerance of ± 0.5% in Malaysian Standard; MS ISO 13006. In other words, it provides for ± 3mm in absolute terms based on the mentioned tile size. If we zoom in to our LEO Ceramiko’s specs of ± 0.25%, we will only allow ± 1.5mm tolerances in Grade A tiles and anything that surpasses it will downgrade as Grade B tiles. Our tile products are capped at ± 1mm to ensure an extremely high-quality standard.

Picture 3: How to determine Straightness of Sides

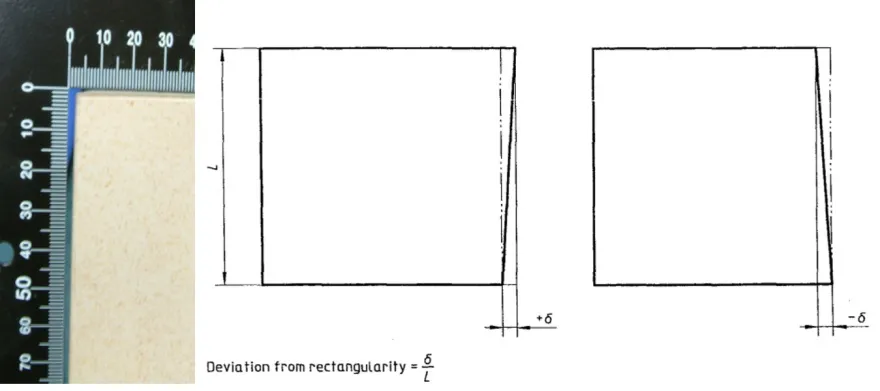

c) Rectangularity, on the other hand, allows for ±6% tolerancesunder MS standard while LEO Ceramiko’s product allows for ± 0.3% maximum tolerances for Grade A tiles. If figures surpass that will be classified as Grade B tiles. That translate to ± 1.8mm max for a 600x600mm tile size. Our rule of thumb will always cap the tolerance at ± 1mm in order to ensure ours are near perfect.

Picture 4: How to determine Rectangularity

In summary, using Grade B tiles will not get you a good alignment when carpet of tiles is laid on the floor where you will end up with crooked grout lines and unsightly floor pattern.

Picture 5: Uneven Grout Sizes if Grade B tiles are used with Inconsistent Tile Size

TOPIC: SURFACE FLATNESS

Picture 6: Equipment used to determine surface flatness

Picture 6: Equipment used to determine surface flatness

Surface Flatness can be measured using the above equipment shown to determine 3 criteria namely:

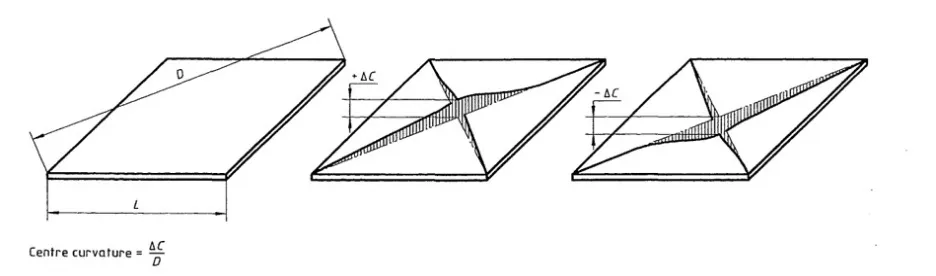

a) Center Curvature

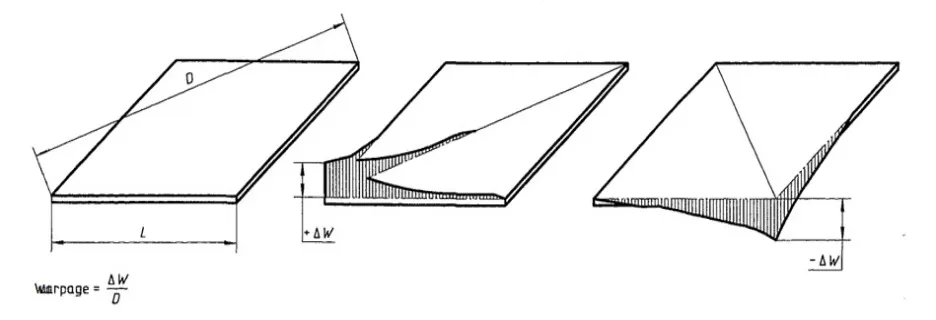

b) Warpage

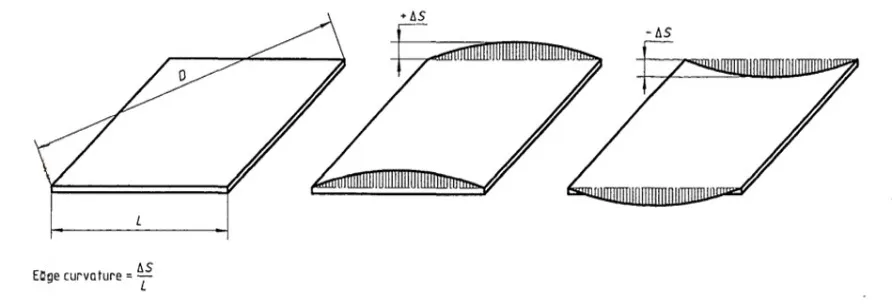

c) Edge Curvature

Customers will not want to have this sort of quality finishes on their floors as shown in Picture 7 below. Therefore, it is paramount that tiles are as flat as it can get by complying to the given standards.

Picture 7: Typical Poor Floor Surface Flatness

a) Center Curvature is measured using a filler gauge with a differing thickness (from 0.1mm to 1mm thick) to slot underneath the straight edge or metal bar by placing the latter on a piece of tile diagonally. The thickness of the filler gauge that can pass through the straight edge will determine the readings and be measured against its tolerance. Tolerance, in this instance, under MS standard is ± 0.5% or ± 4.24mm for 600x600mm tiles where your Diagonal length, D is 848.5mm. LEO Ceramiko’s standard is capped at ±0.25% or ± 2.1mm in absolute millimeter terms of the said size of 600x600mm. Any reading beyond ± 0.25% will downgrade to Grade B tiles.

Picture 8: To Determine Center Curvature

Picture 9: Using Straight Edge and Filler Gauge to determine Center Curvature

Picture 9: Using Straight Edge and Filler Gauge to determine Center Curvature

b) Warpage is measured using a similar method as center curvature but focusing only at any of the 4 corners of a piece of tile. The readings or results that surpass ± 0.25% of the Diagonal length, D will downgrade to Grade B tiles

Picture 10: To Determine Warpage

c) Warpage is measured using a similar method as center curvature but focusing only at any of the 4 corners of a piece of tile. The readings or results that surpass ± 0.25% of the Diagonal length, D will downgrade to Grade B tiles.

Picture 11: To Determine Edge Curvature

Picture 12: Using Straight Edge and Filler Gauge to determine Edge Curvature

Picture 12: Using Straight Edge and Filler Gauge to determine Edge Curvature

If Grade B tiles are the choice, coupled with poor installation skills, it will cause a “lippage” problem shown in Picture 7 where the overall surfaces are uneven. In serious conditions, it can invite injuries by inducing a fall or a trip whenever there is movement around that area.

TOPIC: SURFACE QUALITY

In the list on this topic, there are 11 criteria one can observe when viewing at a stand-tall position with a carpet of tiles (minimum one square meter of tiles) perpendicular from the floor with a minimum distance of 1 meter apart under even light intensity of 300 lux. International standards indicate that 95% of tiles shall be free from visible defects that may impair the overall physical appearances i.e. anything above 5% visible defects which are traceable can downgrade the whole batch to Grade B.

Hence, the Quality Control Department of tile suppliers must play their role in identifying and segregating which are Grade A or Grade B tiles appropriately. We do not wait for our end-user to identify the problem for us as that will be a tad too late.

The 11 criteria of physical appearances are featured as follows:

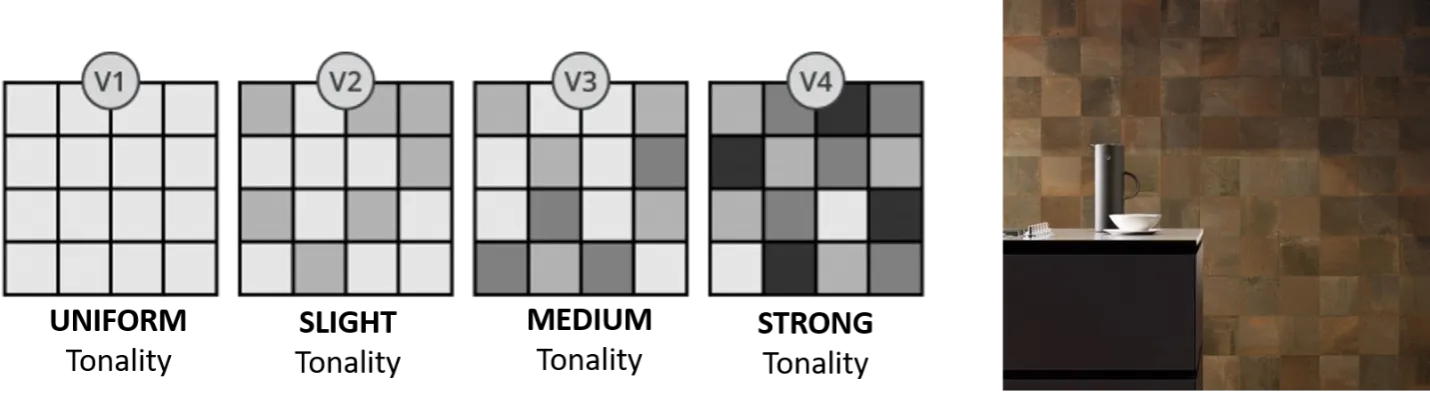

a) Shading

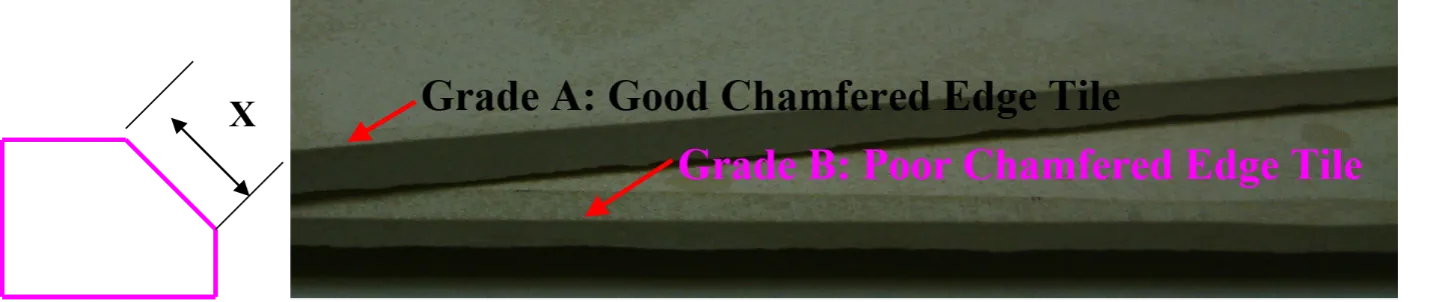

b) Chamfered Edge

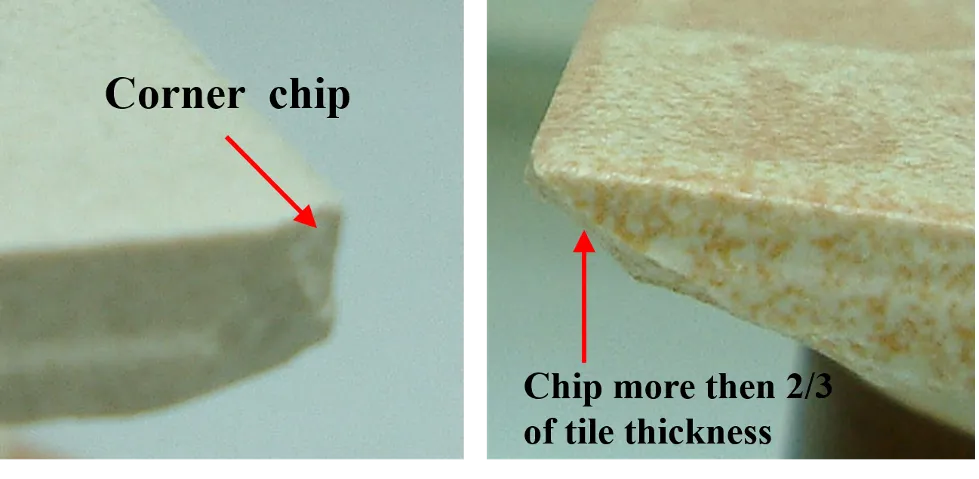

c) Chipping

d) Body Crack

e) Delamination

f) Incomplete Polished Tile

g) Contamination

h) Pin Holes

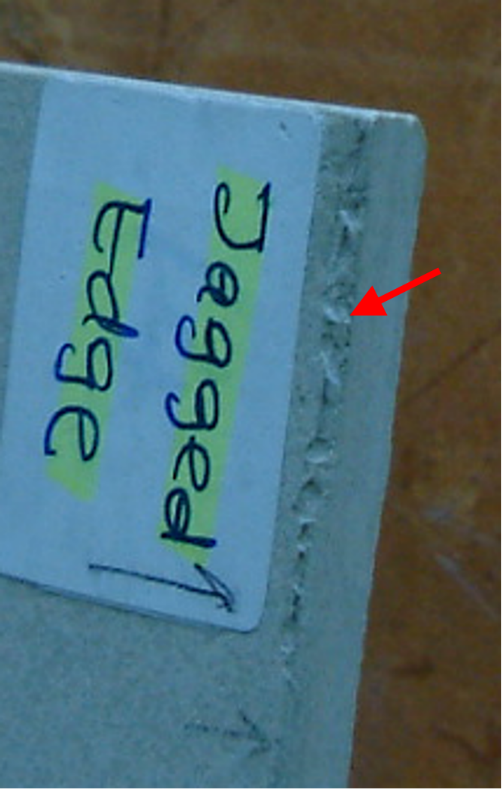

i) Jagged Edges

j) Dimple/Pimple

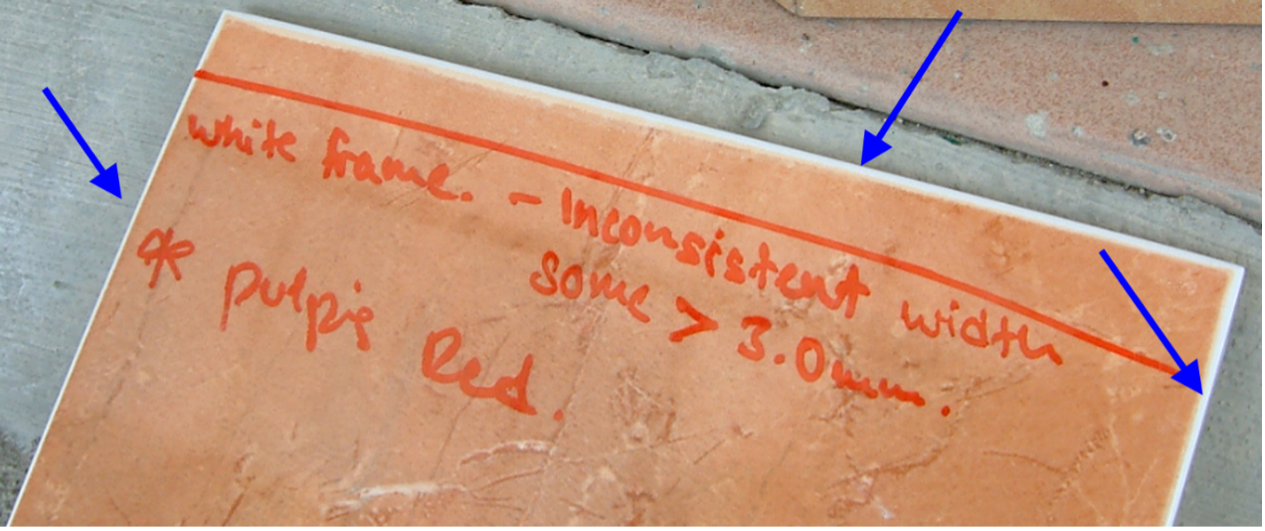

k) Window Frame/White Frame

a) Shading is essentially an inherent characteristic of all ceramic products. The main ingredient of tiles is clay composition. The natural property of shade differences happens whenever a new mining activity of these raw materials takes on at a different interval. In all tile product catalogues, tiles series or collections are segregated into Variation 1 to 4 (V1, V2, V3, and V4) as shown in Picture 13. Try imagining if the catalogue indicated a tile as V1 uniform tonality and the actual tiles delivered are seen something like in the far-right Picture 13 that lean towards V4 with strong tonality, then those tiles are considered Grade B tiles instead.

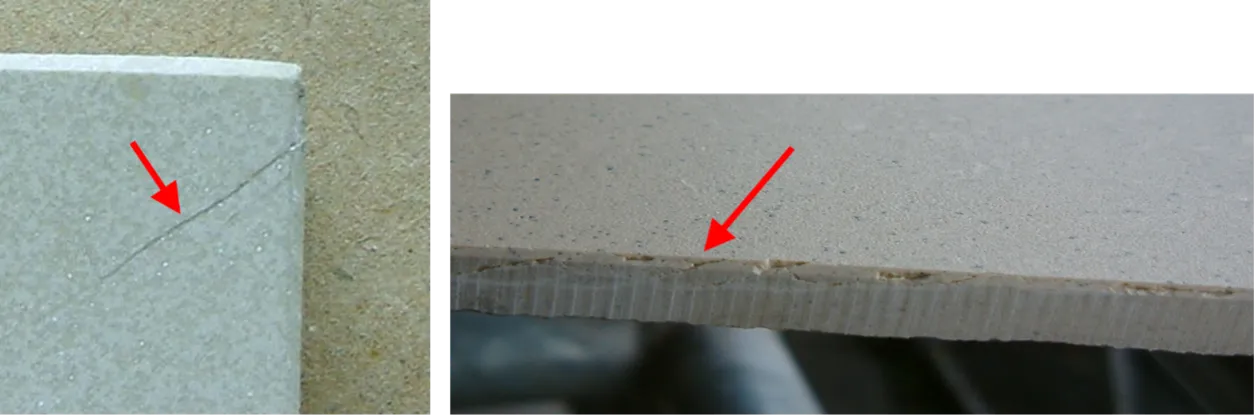

d) Body Cracks can happen whenever there is an abrupt temperature change before or after the firing process. A crack like this is sometimes called a cooling crack. When cracks appear on the surface of tiles, they will be downgraded into Grade B tiles shown in Picture 16.

e) Delamination of tiles happens the same way as body cracks. Grade A tiles are free from this defect. We see this defect not on the surface of Grade B tiles but the chamfered edges or side edges instead.

Picture 17: Delamination of Tile in Grade B tile

f) Incomplete Polished Tile may happen when the polishing line encounters technical glitches where part of the Polished Tiles is not polished evenly by the diamond heads. When we viewed from a meter apart, this mentioned defect is not visible in Grade A tiles while Grade B tiles are visible.

Picture 18: Incomplete Polished Tile

g) Contamination is where foreign substances appear on the tile surface and can be viewed from a meter apart. In a Grade A tile, the defect is not noticeable or smaller than 1mm size.

Picture 19: Contamination

h) Pin Holes, which occur when bubbles are trapped in the tile body and burst after firing, can be apparent when viewed from a meter apart with a size larger than 1mm. These are then considered Grade B tiles. If it is not visible from a meter apart, then Grade A tiles are being classified instead.

Picture 20: Pin Hole

i) Jagged Edges are another problem where tiles encounter during production as shown in Picture 21. They will be downgraded as Grade B as once installed on the floor, it will look unpleasant especially after grouting.

Picture 21: Jagged Edges

j) Dimple/Pimple is similar to Pin Holes where the former is protruding out, and the latter is inverse. When viewed from a meter apart and if it is obvious, then the tiles are downgraded to Grade B tiles.

Picture 22: Dimple/Pimple

k) Window Frame or White Frame is when viewing tiles from a meter apart, we have an obvious frame surrounding the design of the tile. This usually happens when tiles are non-rectified/mono-calibrated like ceramic tiles. Grade A ceramic tiles have a small frame not more than 3mm in width, but for LEO Ceramiko’s ceramic tiles, we do not permit them to appear at all.

Picture 23: Window Frame or White Frame

There you have it with all the physical appearances covered here in the topics above. With that, you can distinguish which constituted Grade A and Grade B tiles. There is one point to note here, where knowledge of tiles is just a means to an end while acquiring knowledge of tiling work with proper preparation is equally important. There are brief topics in our LEO Ceramiko’s website that cover pre-installation, during installation, and post-installation. In our future blogs, we will cover in-depth how to choose the perfect tile for your home as everybody deserves to know the best.

AFTERTHOUGHT

It is our consumer right to request from our suppliers the technical specification, which usually is in their product catalogue, or downloadable from their website, whenever we want to make purchases. If a customer is concerned about the quality of tiles purchased, one can query your suppliers for an explanation based on the governed specs. Please remember to always refer to tile suppliers’ claims on their technical specs on how they differentiate their Grade A and Grade B tile rather than solely relying on MS ISO 13006 standard, which is leniently based. Do keep some extra tiles as well that you purchased earlier. This is to assist you, whenever you are unsatisfied with the explanation given, to send the said samples to an independent test lab like Ceramic Research Company (CRC) or SIRIM to verify against the claimed specs. Remember that Grade A tiles are put on sales responsibly in which tile suppliers are guaranteeing their products against any manufacturing defects.

It is always a good practice or advice for customers to go for tiles suppliers that show their technical specs. If one chooses Grade B tiles over the other because of their lower price, then the responsibility will lie squarely on the customer’s shoulder when these tiles bought have an inferior standard as you cannot have recourse.

#tilesforhome #livingroom #bathroom #bedroom #kitchentiles #floortiles #walltiles #leoceramiko #porcelainceramictiles #outdoorindooruse #wallfloortiles #homeimprovements #interiordesign #interiorfloors #rennovation #exteriordesign #porcelaintiles